|

Roy J. Plunkett - Hall of Fame Entry Author: Plastics Academy Staff Added: 03/29/2004 Type: Summary [ Not Rated Yet ] |

|

Roy J. Plunkett - Hall of Fame Entry Author: Plastics Academy Staff Added: 03/29/2004 Type: Summary [ Not Rated Yet ] |

|

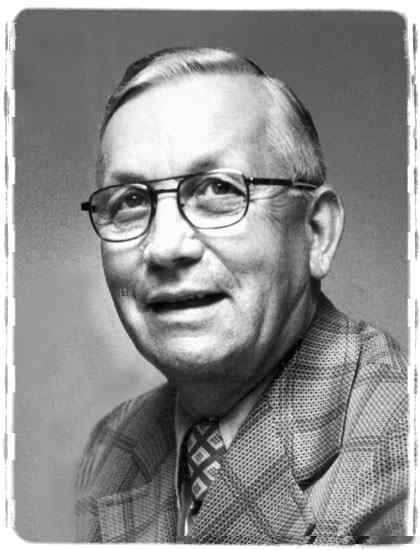

Roy J. Plunkett Birthdate: Deceased: Induction: Material |

Researcher, discoverer of Teflon tetrafluoroethylene resin in 1938, director of operations of the Freon Products Div. of the Organic Chemicals Dept., DuPont Co. Joined the company in 1936. Leadership in the management of research, development, and production has led to numerous new fluorochemical products and processes.

The discovery of polytetrafluoroethylene resin appears in retrospect to have been more than a turning point in fluorine chemistry. It spawned a whole family of new plastics and resins.

It occurred on April 6, 1938, when I opened a steel cylinder that had contained tetrafluoroethylene and found that it had polymerized to a white waxy solid. From this came the development, at DuPont, of Teflon polytetrafluoroethylene resin.

So many useful inventions stemmed from this event that it is difficult to accept the fact that the field of fluorine chemistry was considered to be somewhat "mature" at the time, with really no new development in sight.

From its beginning, Teflon was a stimulus to research leading to a range of useful developments -- an elastomer with excellent resistance to heat, oxidizing conditions, and chemical attack. Today it is serving in gaskets, seals, tubing, and other flexible forms used in severe temperature and chemical conditions. It also led to the development of stain- and moisture-resistant coatings for apparel, carpets, upholstery, and other textile products. Other developments were a grease- and moisture-resistant coating for paper and ingredients in weather-resistant paints. A resistant film was developed that is used for low-maintenance building exteriors.

The early difficulty in learning to fabricate and shape TFE resin gradually gave way to the point where it was possible to form it into a fiber. Textiles made from it are used to make fabric bearings so flow- resistant that they can be used to support bridges.

In the 1950s, copolymers were developed that retained most of the chemical stability and mechanical properties of the original TFE polymer, yet molded or extruded like polyethylene.

After 35 years of development, I see little sign of a slowdown. One indication of still another round of discovery lies in work going on with the perfluorosulfonic compounds -- sometimes called plastic acids. Unlike Teflon, with its well-known hydrophobic property, this new material is one of the most hydrophilic. In the form of a plastic membrane, it performs as a sort of "traffic controller" in separating dissolved solids with great potential impact on electrochemical and chemical processes. Long range, those membranes should have great environmental benefit because they perform separations without requiring heat for vaporization or crystallization and because they can have direct use in pollutant-free processes or in converting pollutants into valuable products. In one city, a membrane-equipped device has been in use for over a year to disinfect sewer water during storm conditions. The basic resin can be made into tubing, laminates, filaments, and fiber.

Even with this sustained flow of new fluoroplastics, the rest of this century will not see them grow in rank as one of the largest families of plastics. But in terms of benefit to mankind and in potential for further development, the outlook is bright. After more than 37 years of working in this field, I am proud to have been a first-hand observer of this growth.